Cold Atmospheric Plasma: Enhancing EV Battery Manufacturing & Performance

As Electric Vehicles become a part of everyday life, manufacturers are required to continually improve battery technology and performance: more energy storage, operating at higher energy densities. Cold Atmospheric Plasma is a pioneering technology that offers a novel solution. By introducing plasma treatments into existing manufacturing processes, it is possible to improve physical bonding of components, increase electrical conductivity of batteries, and increase thermal diffusivity across components.

The Manufacturing Challenge

The future of propulsion systems is electric drivetrains, often powered by electrical energy stored in batteries. With electric cars now commonplace, we are starting to other EVs enter the market, including motorbikes, yachts and light aircraft. To be effective and efficient, batteries for electric vehicles must exhibit good temperature management, be weather resistant, and comprise of a high-quality assembly to ensure a long service life. To achieve these, stable assembly processes that include reliable bonding technologies are essential. The treatment of surfaces using atmospheric plasma technologies is one of the most effective industrial processes for cleaning, activating, or coating plastics, metals, glass and other materials.

The use of plasma to optimise bonding during module assembly processes has the additional benefit of increasing the thermal and electrical conductivity across material junctions. Furthermore, it is a green technology: plasma replaces chemicals, reducing carcinogenic emissions from solvent-containing products.

The Technology Solution

Prismatic cell treatment is performed before isolation, which increases surface energy for improved deposition of isolation paints and activation for cell-to-cell bonding. Between the cells there is heat conductive glue, which needs to remain mechanically strong whilst allowing the cells to thermally cycle. Plasma cleans and changes the micro-topography of the paint surface; this increases the surface area to volume ratio, in turn increasing the rate the cell dissipates thermal energy. Activation is also performed to increase the bonding between prismatic cells and pack bases. A typical pack base material is PolyCarbonate (PC).

Pouch cells have very low mass and high energy density. Originally used in mobile phones, they are now being selected by some leading EV manufactures. Pouch cells require cleaning before laser welding of the electrical connections. Plasma is used to clean and activate the cell surface to improve the bonding with tape or adhesives. Plasma densifies the oxide layer and strengthens it. Organic substances are removed. Plasma deposits free O and OH groups for increased adhesion. When cells charge and discharge, they expand and contract, which is a challenge for adhesion and thermal dissipation: plasma adds value by also improving the thermal diffusivity across component surfaces.

Cylindric cells were originally pioneered by Tesla. The outside top surfaces of the individual cells are bonded to a polymer frame to ensure physical alignment. A thin wire is ultrasonically welded to the top of the cell, then connected to a busbar. If contamination is present on the surface of the cell electrode, the bond to the wire will fail. A plasma clean can be used to prevent this from happening, ensuring components are made right the first time.

Glycol coolant is run through battery packs to extract thermal energy, often carried by aluminium Serpentine cooling tubes. These tubes must remain electrically insulated, so a Mylar polymer is wrapped around them. Polymers can be notoriously tricky to bond, so a plasma pre-treatment improves both this bond, and the bond between each Mylar-covered tube.

Plasma processing, therefore, increases the physical bonding of the components inside a battery pack, increases the electrical conductivity of the batteries, and increases the thermal diffusivity across the component surfaces.

The Science – Processing with the Adtec 50W PlasmaTact

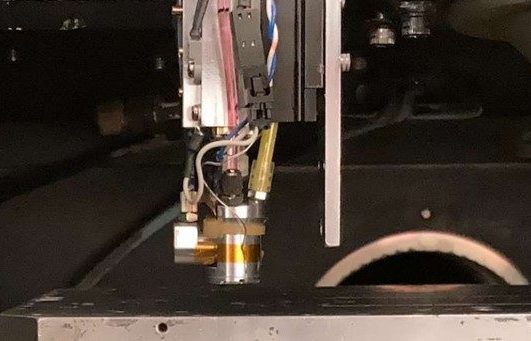

The Adtec PlasmaTact is a microwave induced cold plasma torch that generates argon plasma. By installing the device in a CNC machine, we performed surface energy modification on these key materials to enhance the battery manufacturing process.

Mylar, Polycarbonate and Aluminium 6082 were processed, and a metric called water contact angle was used to quantify the surface modification. A reduced contact angle = increased wettability = improved bonds.

Figure 6 demonstrates how the plasma creates regions of super-hydrophilicity, causing water to stick preferentially to the treated area. The 50W PlasmaTact modifies the surface energy (increased surface energy = increased wettability = improved bonding) of the component surfaces. As well as improved physical bonding, the process improves both electrical bonding and thermal diffusivity across the component surfaces.

To find our more about Adtec’s pioneering cold plasma technology, please contact us here.