PlasmaTact for Surface Energy Modification and Bonding on Aerospace Composites

Introduction

The aerospace sector is pushing towards sustainability and reduction in their carbon emissions, as a result, there is a demand for lighter and more fuel-efficient aircraft. ‘Light weighting’ can be achieved using fibre-reinforced composite materials to construct primary and secondary structures of an aircraft. Circa 50% of the mass of the Boeing 787 ‘Dreamliner’ is accounted for by composite materials. Advantages such as excellent fatigue life, corrosion resistance, and improved thermal and electrical properties coupled with the weight-saving capability make fibre-reinforced composite materials desirable to aircraft manufacturers.

![Usage of composites in Boeing 787 Dreamliner structure [22].](https://www.researchgate.net/publication/320951033/figure/fig1/AS:631662626996225@1527611514245/Usage-of-composites-in-Boeing-787-Dreamliner-structure-22.png)

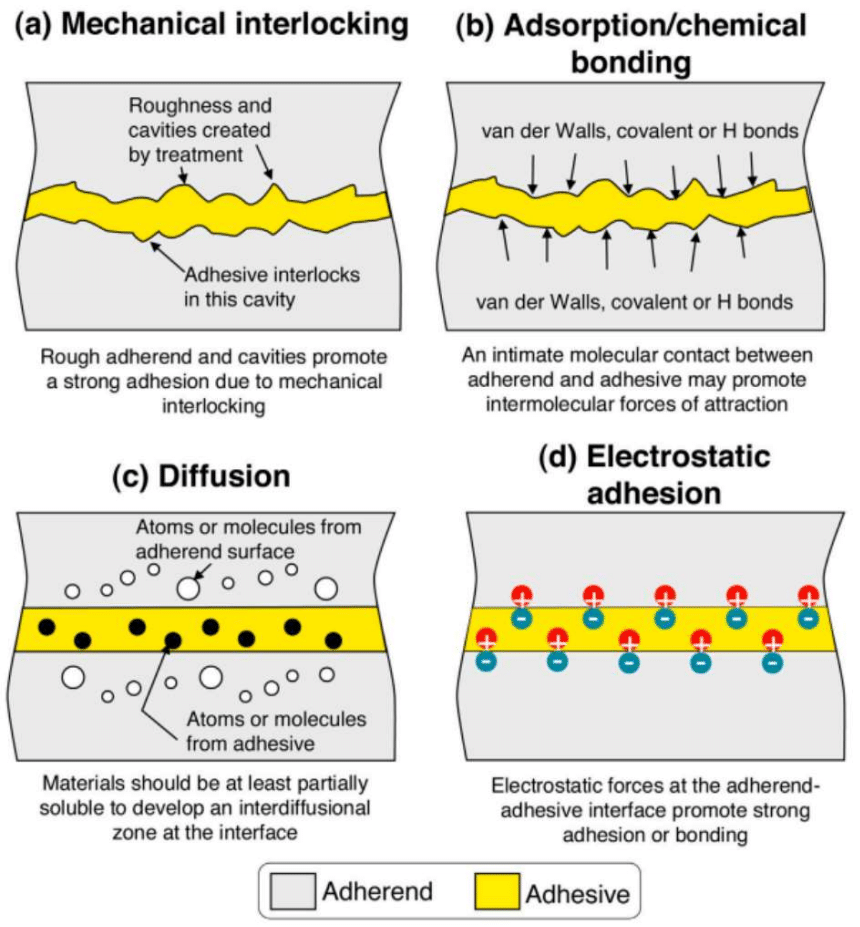

The most common surface treatments are techniques such as sanding or grit blasting that physically abrade the bond surface, increasing the surface roughness that aids in mechanical interlocking between the adhesive and the adherend. These preparation techniques produce dust, which is undesirable for bonding, so solvent cleaning is usually performed after sanding. Plasma treatments are gaining widespread application in the automotive and aerospace industry as they not only clean the surface, but also change the chemical composition and surface energy aiding in an improved bonded joint.

Plasma treatments are gaining widespread application in the automotive and aerospace industry as they not only clean the surface, but also change the chemical composition and surface energy aiding in an improved bonded joint.

PlasmaTact 50 Testing

The main effects of plasma treatment on a composite surface are: modifying surface roughness due to the ablation effect; removal of contaminants; and, altering the surface chemistry. Hence, treatment of the composite adherends using plasma may activate both the mechanical interlocking and the chemical bonding adhesion mechanisms, maximising the adhesive bond strength. Concerning surface chemistry, research has found that it generally improves the oxygen content and creates polar components on the surface, which are essential for adhesive bonding [v]. Due to all these advantages,plasma treatment is gaining widespread applications in the aerospace and automotive sectors for use in adhesive bonding, with one of the most used plasma treatment systems being Atmospheric Pressure Plasma (APP) systems, due to their low operating costs and ease of use.

Surface Treatments

All composite samples were cleaned in an ultrasonic bath for 20 minutes before treatment. One set of samples was treated and characterised. For solvent cleaning, Isopropanol was used. For sanding, 240-grit sandpaper was used to abrade the surface in random directions; the grit size and sanding directions were chosen based on literature. The plasma torch parameters were set so that the optimal plasma was discharged for surface energy modification using pure argon gas: 50 W forward power, 0 W reflected power, 2.48 GHz frequency, 10 L/min gas flow rate, a 3 mm stand-off distance, and a processing speed of 1m/min.

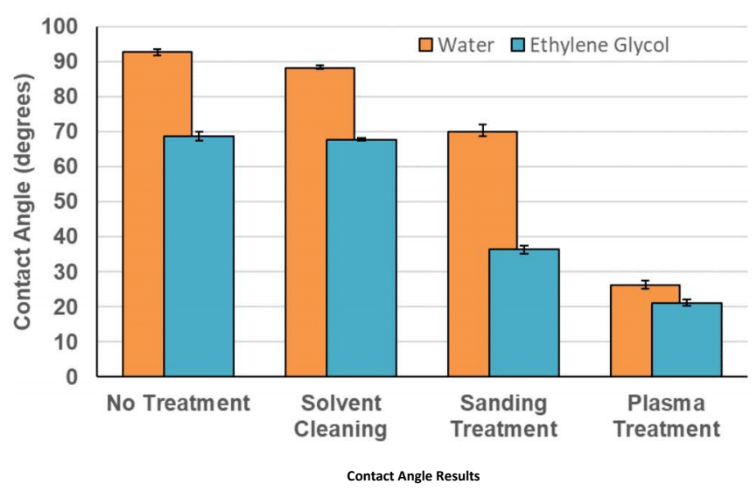

Contact Angle (lower is better)

The non-treated sample has a hydrophobic surface, with a water contact angle of 92.1° and an ethylene glycol contact angle of 68.7°. Ethylene glycol contact angle will always be lower than water, on this material, as it has lesser surface tension. The solvent-cleaned sample has a marginally reduced contact angle; however, the sanding-treated samples have significantly reduced contact angles of 70.0°and 36.3° for water and ethylene glycol, respectively. Plasma treatment has a bigger reduction in contact angle: 26.1° and 21.1°, signifying a highly energised, hydrophilic surface.

Surface Energy (Higher is better)

The contact angles in Figure 10 were then used with the Wendt, Rabel and Kaelble method, to determine the surface energy of each composite sample. Figure above shows the results. The plasma

treated surface has the highest surface energy of 74.5mJ/m2, followed by the sanding-treated samples with a value of 37.1mJ/m2. The non-treated and solvent-cleaned samples have low surface energies of 20.7mJ/m2 and 22.0mJ/m2, respectively.

Surface Roughness (Lower is better)

The non-treated, solvent cleaned, and plasma treated samples have low roughness values of 0.16μm, 0.18μm, and 0.18μm, Ra, respectively. The sanding treatment has the highest Ra value of 0.64μm, because of the physical abrasion from the sandpaper.

Lap Shear Failure Load (Higher is better)

The average failure loads of the hybrid plasma treatment were lower than the plasma treated only specimens, which is an important outcome. Plasma treatment alone, was better than using any other treatment and better than using a hybrid approach with the next best treatment method.

Conclusion

The 50W Plasma Tact from Adtec Plasma improved the bonding strength of a carbon fibre composite. The plasma treatment may also be used, on it’s own, without the need for using traditional solvents or sand blasting techniques.

For more information regarding the PlasmaTact Series, click here.