PlasmaTact for Surface Energy Modification and Bonding on Aerospace Composites

Introduction

The aerospace sector is pushing towards sustainability and reduction in their carbon emissions, as a result, there is a demand for lighter and more fuel-efficient aircraft. ‘Light weighting’ can be achieved using fibre-reinforced composite materials to construct primary and secondary structures of an aircraft. Circa 50% of the mass of the Boeing 787 ‘Dreamliner’ is accounted for by composite materials. Advantages such as excellent fatigue life, corrosion resistance, and improved thermal and electrical properties coupled with the weight-saving capability make fibre-reinforced composite materials desirable to aircraft manufacturers.

![Usage of composites in Boeing 787 Dreamliner structure [22].](https://www.researchgate.net/publication/320951033/figure/fig1/AS:631662626996225@1527611514245/Usage-of-composites-in-Boeing-787-Dreamliner-structure-22.png)

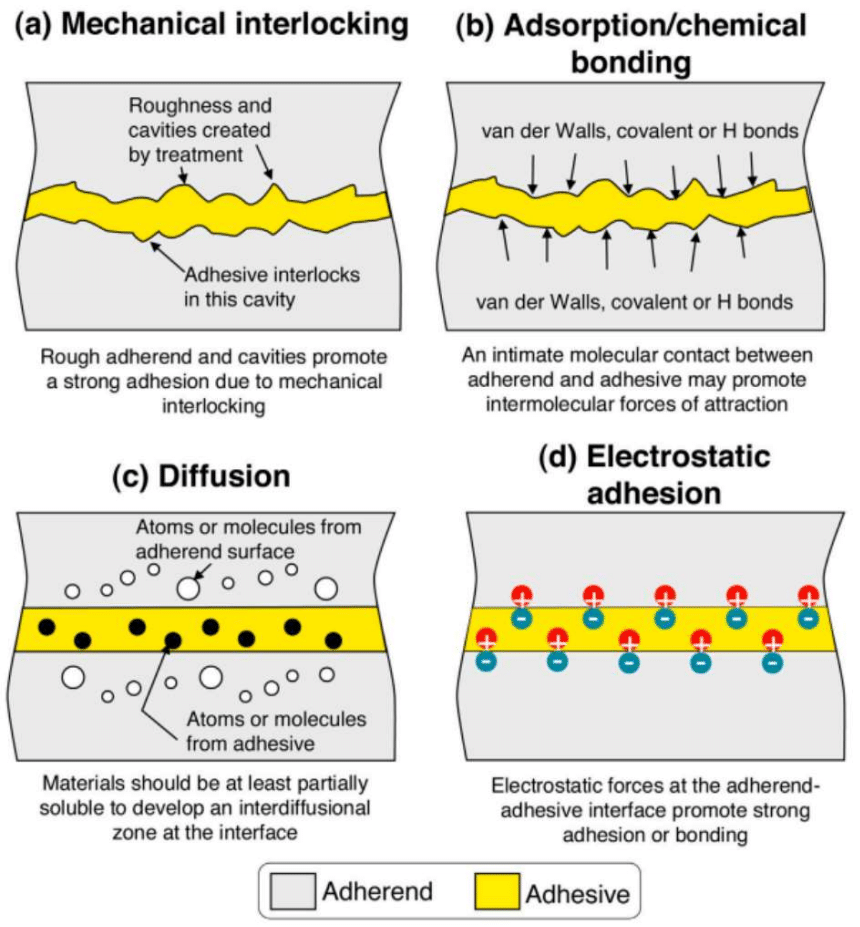

The most common surface treatments are techniques such as sanding or grit blasting that physically abrade the bond surface, increasing the surface roughness that aids in mechanical interlocking between the adhesive and the adherend. These preparation techniques produce dust, which is undesirable for bonding, so solvent cleaning is usually performed after sanding. Plasma treatments are gaining widespread application in the automotive and aerospace industry as they not only clean the surface, but also change the chemical composition and surface energy aiding in an improved bonded joint.

Plasma treatments are gaining widespread application in the automotive and aerospace industry as they not only clean the surface, but also change the chemical composition and surface energy aiding in an improved bonded joint.

PlasmaTact 50 Testing

The main effects of plasma treatment on a composite surface are: modifying surface roughness due to the ablation effect; removal of contaminants; and, altering the surface chemistry. Hence, treatment of the composite adherends using plasma may activate both the mechanical interlocking and the chemical bonding adhesion mechanisms, maximising the adhesive bond strength. Concerning surface chemistry, research has found that it generally improves the oxygen content and creates polar components on the surface, which are essential for adhesive bonding [v]. Due to all these advantages,plasma treatment is gaining widespread applications in the aerospace and automotive sectors for use in adhesive bonding, with one of the most used plasma treatment systems being Atmospheric Pressure Plasma (APP) systems, due to their low operating costs and ease of use.

Surface Treatments

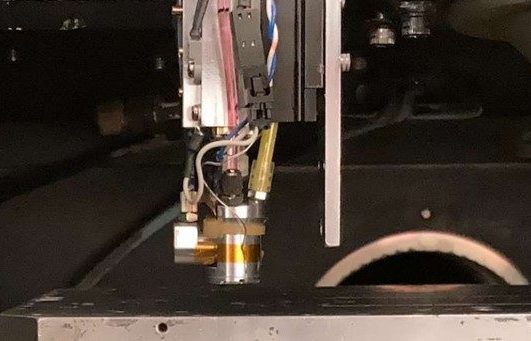

All composite samples were cleaned in an ultrasonic bath for 20 minutes before treatment. One set of samples was treated and characterised. For solvent cleaning, Isopropanol was used. For sanding, 240-grit sandpaper was used to abrade the surface in random directions; the grit size and sanding directions were chosen based on literature. The plasma torch parameters were set so that the optimal plasma was discharged for surface energy modification using pure argon gas: 50 W forward power, 0 W reflected power, 2.48 GHz frequency, 10 L/min gas flow rate, a 3 mm stand-off distance, and a processing speed of 1m/min.

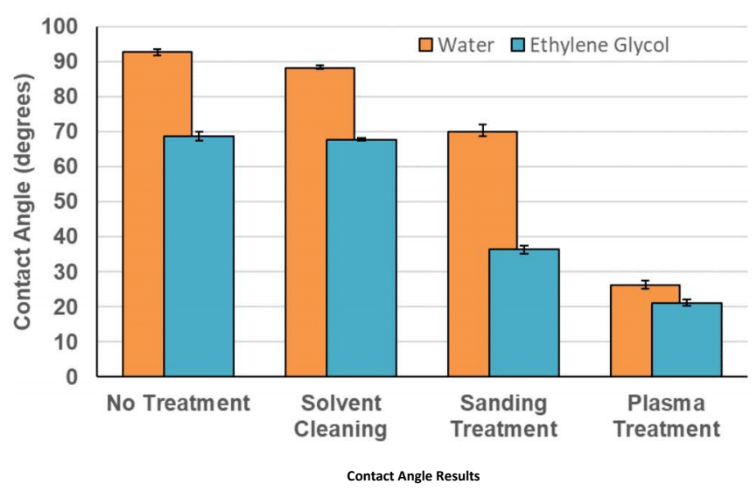

Contact Angle (lower is better)

The non-treated sample has a hydrophobic surface, with a water contact angle of 92.1° and an ethylene glycol contact angle of 68.7°. Ethylene glycol contact angle will always be lower than water, on this material, as it has lesser surface tension. The solvent-cleaned sample has a marginally reduced contact angle; however, the sanding-treated samples have significantly reduced contact angles of 70.0°and 36.3° for water and ethylene glycol, respectively. Plasma treatment has a bigger reduction in contact angle: 26.1° and 21.1°, signifying a highly energised, hydrophilic surface.

Surface Energy (Higher is better)

The contact angles in Figure 10 were then used with the Wendt, Rabel and Kaelble method, to determine the surface energy of each composite sample. Figure above shows the results. The plasma

treated surface has the highest surface energy of 74.5mJ/m2, followed by the sanding-treated samples with a value of 37.1mJ/m2. The non-treated and solvent-cleaned samples have low surface energies of 20.7mJ/m2 and 22.0mJ/m2, respectively.

Surface Roughness (Lower is better)

The non-treated, solvent cleaned, and plasma treated samples have low roughness values of 0.16μm, 0.18μm, and 0.18μm, Ra, respectively. The sanding treatment has the highest Ra value of 0.64μm, because of the physical abrasion from the sandpaper.

Lap Shear Failure Load (Higher is better)

The average failure loads of the hybrid plasma treatment were lower than the plasma treated only specimens, which is an important outcome. Plasma treatment alone, was better than using any other treatment and better than using a hybrid approach with the next best treatment method.

Conclusion

The 50W Plasma Tact from Adtec Plasma improved the bonding strength of a carbon fibre composite. The plasma treatment may also be used, on it’s own, without the need for using traditional solvents or sand blasting techniques.

For more information regarding the PlasmaTact Series, click here.

Cold Atmospheric Plasma: Enhancing EV Battery Manufacturing & Performance

As Electric Vehicles become a part of everyday life, manufacturers are required to continually improve battery technology and performance: more energy storage, operating at higher energy densities. Cold Atmospheric Plasma is a pioneering technology that offers a novel solution. By introducing plasma treatments into existing manufacturing processes, it is possible to improve physical bonding of components, increase electrical conductivity of batteries, and increase thermal diffusivity across components.

The Manufacturing Challenge

The future of propulsion systems is electric drivetrains, often powered by electrical energy stored in batteries. With electric cars now commonplace, we are starting to other EVs enter the market, including motorbikes, yachts and light aircraft. To be effective and efficient, batteries for electric vehicles must exhibit good temperature management, be weather resistant, and comprise of a high-quality assembly to ensure a long service life. To achieve these, stable assembly processes that include reliable bonding technologies are essential. The treatment of surfaces using atmospheric plasma technologies is one of the most effective industrial processes for cleaning, activating, or coating plastics, metals, glass and other materials.

The use of plasma to optimise bonding during module assembly processes has the additional benefit of increasing the thermal and electrical conductivity across material junctions. Furthermore, it is a green technology: plasma replaces chemicals, reducing carcinogenic emissions from solvent-containing products.

The Technology Solution

Prismatic cell treatment is performed before isolation, which increases surface energy for improved deposition of isolation paints and activation for cell-to-cell bonding. Between the cells there is heat conductive glue, which needs to remain mechanically strong whilst allowing the cells to thermally cycle. Plasma cleans and changes the micro-topography of the paint surface; this increases the surface area to volume ratio, in turn increasing the rate the cell dissipates thermal energy. Activation is also performed to increase the bonding between prismatic cells and pack bases. A typical pack base material is PolyCarbonate (PC).

Pouch cells have very low mass and high energy density. Originally used in mobile phones, they are now being selected by some leading EV manufactures. Pouch cells require cleaning before laser welding of the electrical connections. Plasma is used to clean and activate the cell surface to improve the bonding with tape or adhesives. Plasma densifies the oxide layer and strengthens it. Organic substances are removed. Plasma deposits free O and OH groups for increased adhesion. When cells charge and discharge, they expand and contract, which is a challenge for adhesion and thermal dissipation: plasma adds value by also improving the thermal diffusivity across component surfaces.

Cylindric cells were originally pioneered by Tesla. The outside top surfaces of the individual cells are bonded to a polymer frame to ensure physical alignment. A thin wire is ultrasonically welded to the top of the cell, then connected to a busbar. If contamination is present on the surface of the cell electrode, the bond to the wire will fail. A plasma clean can be used to prevent this from happening, ensuring components are made right the first time.

Glycol coolant is run through battery packs to extract thermal energy, often carried by aluminium Serpentine cooling tubes. These tubes must remain electrically insulated, so a Mylar polymer is wrapped around them. Polymers can be notoriously tricky to bond, so a plasma pre-treatment improves both this bond, and the bond between each Mylar-covered tube.

Plasma processing, therefore, increases the physical bonding of the components inside a battery pack, increases the electrical conductivity of the batteries, and increases the thermal diffusivity across the component surfaces.

The Science – Processing with the Adtec 50W PlasmaTact

The Adtec PlasmaTact is a microwave induced cold plasma torch that generates argon plasma. By installing the device in a CNC machine, we performed surface energy modification on these key materials to enhance the battery manufacturing process.

Mylar, Polycarbonate and Aluminium 6082 were processed, and a metric called water contact angle was used to quantify the surface modification. A reduced contact angle = increased wettability = improved bonds.

Figure 6 demonstrates how the plasma creates regions of super-hydrophilicity, causing water to stick preferentially to the treated area. The 50W PlasmaTact modifies the surface energy (increased surface energy = increased wettability = improved bonding) of the component surfaces. As well as improved physical bonding, the process improves both electrical bonding and thermal diffusivity across the component surfaces.

To find our more about Adtec's pioneering cold plasma technology, please contact us here.

Adtec PlasmaTact produces super hydrophilic surface on CSP glass at 30m/min

Adtec's new 50W PlasmaTact is capable of generating super hydrophilic surfaces on Concentrating Solar Power glass at speeds of 30 metres per minute, or half a metre per second, in just one pass of the material's surface.

A super hydrophilic surface is defined as one with a water contact angle of less than 5 degrees, and is a significant result for high-precision plasma torch processing.

In the context of CSP, producing a super hydrophilic surface means we could greatly reduce the water required for cleaning. Beyond this, creating such surfaces can greatly enhance our ability to bond materials.

The video below shows the 50W PlasmaTact, the latest development in Adtec's patented microwave induced argon plasma, processing the surface of the glass at 30m/minute. The image shows the resulting areas of super hydrophilicity - the water sticks preferentially to the treated regions.

Adtec launches 50W Cold Atmospheric Plasma Torch

Adtec first started to investigate cold atmospheric plasma back in 2005, as part of an anti-bacterial study in collaboration with the Max Planck Institute in Germany.

From here, we developed our patented coaxial microwave plasma technology, which remains at the core of our cold plasma products to this day.

As well as medical applications, Adtec developed PlasmaTact - a 15W torch for surface treatments and anti-bacterial applications.

We are now proud to announce the new, higher power 50W PlasmaTact. The increased power means that not only can we perform the same surface treatment tasks at higher speed, but a greater breadth of surface engineering applications become a possibility - keep an eye out for news on our upcoming work exploring etching and deposition at atmospheric pressure!

Adtec expands manufacturing facility in Vietnam

With the semiconductor industry booming, Adtec has invested 20 million USD in expanding our manufacturing facility in Vietnam.

Despite COVID restrictions greatly reducing the output of the Adtec manufacturing plan in Vietnam for large periods of time, the factory is now operating at almost full capacity, and subsequently large investments are being made to ensure Adtec keeps pace with the rapidly growing requirements for semiconductors.

Building 2 will add a further 15,950 square metres of factory space to the site. A 6,675 square metre car park is also included in the development plans.

Starting in September, the factory is scheduled to be ready and operational by July 2023